TRYON BLOG

13 Burning Questions for a Captain of WMS Industry: Erhan Musaoglu

We’ll now be interspersing “Burning Question” interviews with experienced WMS professionals and industry leaders into our “Info Dock” Blog, and to kick-off our interview series we scored the latter with a true captain of industry in the WMS space: Erhan Musaoglu

Erhan Musaoglu is Founder and CEO of Logiwa, a cloud fulfillment platform for high-volume direct-to-consumer (DTC) and omnichannel businesses. With more than 20 years of experience in the warehouse management industry and deep expertise in industrial engineering, he has started multiple logistics companies, including Unitec and IFS. In 2012, he started LA Software, an on-premise reseller and implementor of systems like RedPrairie (now Blue Yonder), Mantis, Descartes and Snycron. Seeing the opportunity for further growth and predicting the industry would move towards cloud-based solutions, he founded Logiwa, a cloud-based WMS software solution. His expertise and leadership in navigating the enterprise and B2B industry has led Logiwa to grow exponentially since its inception in 2017.

1. What drew you to the supply chain arena, and the warehouse management system (WMS) space in particular?

Think of a company as a human body where the warehouse serves as the heart. It pumps blood, a.k.a. inventory, through each and every part of the fulfillment network. From receiving orders to final delivery, the flow of blood cannot stop, and must circulate at a specific frequency, in order to keep everything functioning. Without a steady supply of blood, the other organs will fail. In e-commerce environments, this idea becomes even more important because businesses are racing against time. This mindset drew me to the warehouse space because I saw its importance and the improvements we could make.

As an engineer I saw the obstacles and limitations faced by existing warehouse management systems, as well as the fundamental ways in which the movement and storage of inventory needed to be transformed to better meet increasing consumer demand. I wanted to address these complex issues of DTC fulfillment head-on by building a simple, yet impactful solution capable of empowering operations.

2. From what you’ve seen in recent years at warehouses and distribution centers, what single area deserves the most focus and improvement?

Automation and AI deserve the most attention and improvement. By this, I simply mean that both have amazing potential and benefits to offer. Many forms of automation are already being adopted by more than half of today’s retail and logistics professionals for a reason. From robotics to workflows, the effects of AI-powered automation on operational efficiency and cost savings are undeniable, and necessity is driving more advancements each year.

As e-commerce has grown, so have the logistical challenges of DTC operations: evolving consumer expectations, fluctuations in demand, complex high-volume order management, steep fulfillment standards, and increasing competition between third-party logistics providers. Those challenges add layers of complexity to warehouse operations and necessitate the use of AI and automation to be dealt with effectively. Amplifying the functionalities of AI will help elevate the success of supply chain logistics on virtually every level. Logiwa WMS was designed with these elements as its foundation.

3. What is the most promising trend you’ve noticed in our space and what is the most concerning?

Self-learning, AI-driven algorithms present the most promising trend for our industry. It offers a direct pathway to increasing the efficiency of high-volume DTC warehouse operations, and it enhances the flexibility and scalability of businesses like nothing else can. With this technology, businesses are able to exercise higher levels of accuracy, streamline workflows, and react proactively to changes occurring throughout their supply chain and warehouse operations. Most importantly, they can optimize facility and order management to ensure higher rates of fulfillment and customer satisfaction – all while focusing on growing their business.

To put it into perspective, one of Logiwa’s clients is now able to process 2000 more orders a day, saving an average of $22,650 each month, because of switching to our Tier-1 WMS. Our AI-powered cloud fulfillment platform helped them enhance their picking process by grouping like orders, optimizing their pickers’ walking paths, and streamlining the sorting and packing process.

To speak to potential concerns, self-learning AI-driven algorithms do require high-quality data to work, and many operations aren’t always prepared for the level of data hygiene and data integrity required to get it right. The complexity of an AI-powered supply chain can become burdensome if handled incorrectly. Warehouses will need to take care in timing their adoption of this technology, and have not only the right technology but dependable resources in place to support it.

4. How are the warehouses you’ve worked with managing the transition to automation, and have you seen any bumps in the road or is it mostly smooth sailing?

With a top-tier solution and implementation team, I’d argue that smooth sailing is a possibility for any warehouse operation. Logiwa has perfected the onboarding process with four distinct phases, including: business process and change analysis, configurations testing, training and practices, dry-runs, assisted go-live, and follow-up support. We can get large warehouses or multiple warehouses up-and-running within a matter of weeks.

Unfortunately, the transition does not always play out flawlessly and it is usually the result of an operation’s inventory structure or physical layout. All automation solutions require clean, dependable data in order to work effectively. If a warehouse does not have a well-defined inventory approach or a warehouse layout, it shows during the go-live. It’s also not uncommon to come across a unique situation that was not accounted for during process documentation and onboarding, which requires more tweaks before automation can deliver perfect results.

5. What is the most underrated Key Performance Indicator (KPI) in warehousing?

There are countless KPIs worth tracking. But an operation’s fulfillment accuracy rate, or the ratio of error-free orders over the total number of orders shipped, is absolutely one of the quickest ways to evaluate the health of an operation. If this KPI is where it should be – I’d say at least 98% or higher these days – you can assume that a majority of your warehouse processes and strategies are working as they should.

While this metric does not reflect cost-efficiency or on-time delivery, it is the KPI that can have the most significant impact on customer loyalty, brand image, and your ability to grow. Few things are more costly to DTC warehouse operations than mis-shipments and excessive returns.

6. What is the most misused (used improperly and/or neglected) feature in modern day WMSes?

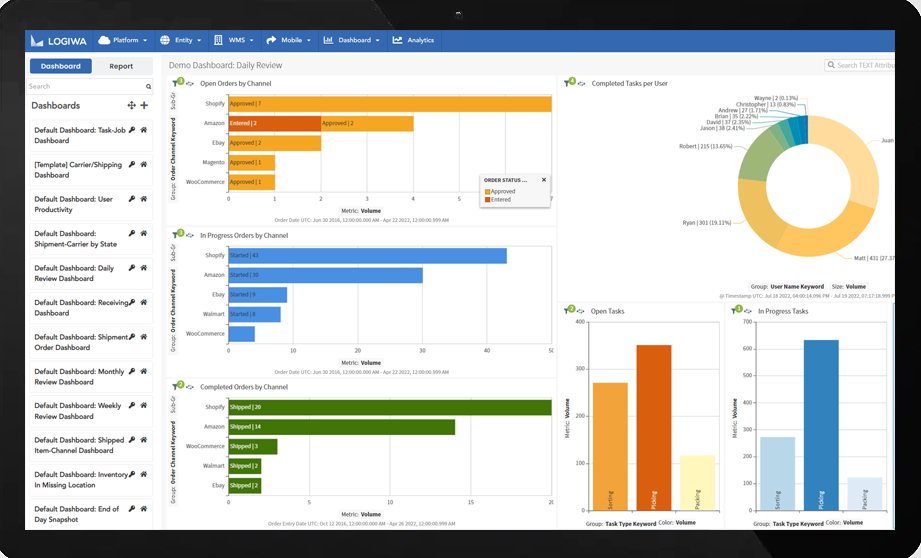

Analytics! Modern WMS solutions are designed with BI tools and configurable analytics features to help warehouse managers plan ahead, eliminate bottlenecks, and make informed decisions for their supply chain operations. Predictive analytics are also underutilized. Rather than use the data flowing through a WMS reactively or wait for an issue to arise, operations can leverage the information accumulating within their WMS solution to maintain accurate inventory levels, optimize labor management, bolster efficiency and develop new strategies for tackling both current and future demand.

7. What is the most common problem you come across during the cutover phase, and how can it be avoided?

It may surprise you, but one of the most common problems we see is not actually a technical issue, but a human issue: nervousness about launching new software. Our 3PL partners often face reluctance from clients around being the first one to officially switch over to a new WMS system. After weeks of careful setups, integration work, testing, and training – it’s actually warehouses’ clients that do not want to be the first to start using the solution on live orders. This changes once they’ve seen another client move through the go-live phase without any major issues or setbacks.

Logiwa helps avoid this problem by empowering operators with hands-on training, conducting ample testing, and offering to process the first few orders alongside operators – which, by extension, instills confidence in their clients. Switching to a new WMS takes willingness from both warehouse operators and the clients they serve, but this can be nurtured by WMS providers. Logiwa fosters readiness for warehouse staff and their clients with a comprehensive and successful implementation process.

8. Where do your clients see the most ROI post-WMS adoption?

Overall, I believe we see the most ROI in terms of throughput, which includes labor efficiency and order processing. Labor, itself, makes up about 60-70% of a warehouse’s operational budget. Logiwa’s fulfillment solution helps optimize inventory allocation within a facility, order creation and processing, employee picking paths, carrier selection, and more with smart automation. By expediting every process, we allow for growth without the need for additional labor.

With so many manual processes, even administrative ones, able to be simplified, refined, sped up – our clients are able to accomplish more than ever post-WMS adoption. For example, in a recent impact survey we conducted, one of our clients showed they were able to reduce their label making process from five minutes down to 26 seconds. Another took their packing process from a 7.5-minute task down to just one minute.

By streamlining workflows with intelligent automation, our clients are able to simplify day-to-day operations for their workers and ship hundreds of orders each day without adding additional headcount. Logiwa customers see a 40% increase in labor efficiency and ship 3x more orders shipped after only three months using our cloud fulfillment platform – leading to thousands of dollars in savings on average each month.

9. What are the key differences between a traditional WMS and fulfillment solution?

I think it’s important to start answering this question by clarifying the difference between warehouses and fulfillment centers. Warehouses store products mid-term and long-term for businesses, and they tend to ship items in bulk. Fulfillment centers provide short-term storage. They are built to receive products, process online orders, and ship completed orders out to consumers. For fulfillment centers, the goal is ultimately to get products in and out of their facility as quickly and efficiently as possible.

A traditional WMS helps manage and control the various processes happening within a warehouse. A higher tier solution can even offer a basic form of workflow automation and connect to certain solutions, such as warehouse control systems (WCS) retrieval systems (ASRS), conveyors, replenishment systems, certain types of robotics, and so on. They are designed to help warehouses move away from strictly manual operations to automated ones.

A fulfillment solution, like Logiwa, on the other hand, does all that and more. It offers the highest degree of functionality for managing not only internal warehouse processes, but order processing, system integrations and workflow automation as well. From the moment an order is placed on an ecommerce platform, a fulfillment solution can route it to the best warehouse and track its progress all the way up until it leaves the fulfillment center.

Because fulfillment solutions like Logiwa’s come pre-integrated with ecommerce, shipping, accounting and ERP platforms, and offer built-in tools (i.e. measurement and currency rate exchanges, dimensioning tools, rate shopping, etc.) they can streamline workflows and optimize the efficiency of fulfillment logistics because they are capable of processing all relevant data within one platform. This helps businesses maintain live visibility and control over complex supply chains and high-volume DTC order fulfillment operations.

10. Is there a clear, delineated line between requirements where company management would know whether they need a WMS or a fulfillment solution?

If you deal with ecommerce orders – regardless of whether they are B2B, DTC, or hybrid in nature – a traditional WMS does not have the required capabilities to manage the complexities of high-volume fulfillment competitively. Especially if you’re a multi-warehouse operation or span across multiple states or countries – you need the visibility and control only a fulfillment solution can provide.

I think the primary question comes down to this: do you want a short-term solution that will need to be upgraded or replaced as you grow? Or do you want an all-in-one fulfillment solution that can connect the critical systems affecting your business and streamline workflows as you grow? A fulfillment solution makes it easy to add new warehouses in, clients and inventory, as well as expedite fulfillment processes with configurable automation as your company evolves. It is equipped for the rapidly changing conditions of modern ecommerce.

11. What features should a company in the market for a fulfillment solution look for when shopping around?

It largely depends on the unique challenges and goals faced by the individual operation, but I’d suggest focusing on time-to-value. This is my number one criteria when talking to companies about choosing a fulfillment solution – as well as integration and automation capabilities. As an ecommerce operation, you cannot afford to disrupt your warehouse with a system that isn’t going to end up paying for itself quickly – and having easy data exchange and highly customizable automation capabilities between the various systems feeding your fulfillment solution is paramount.

And time-to-value is not just about initial investment or how long it takes to see the benefits of a new fulfillment solution post-adoption. It is also about finding the platform that delivers new advantages with every update… one that ensures ever-growing profit margins in a variety of ways. In other words, you need to find a solution that delivers sustainable and ongoing value to you and your business. Our DTC fulfillment solution has an incredibly fast time-to-value due to its easy configurability and industry-leading implementation of just 8-12 weeks.

12. What does the future of WMS look like? Where are we headed?

AI and machine learning are the future of fulfillment. Today’s warehouses need DTC fulfillment solutions capable of continuously boosting efficiency, adapting order management intuitively (and in real-time), and providing ongoing improvements to fulfillment strategies to help supply chains reach their full potential. These two aspects of the modern WMS help operations stay ahead of growing consumer demand and make the course corrections necessary to compete in the future fulfillment landscape.

13. If you could hire one famous person and add them to your team at Logiwa who would you choose and why?

To me, the people at Logiwa are already stars. Our organization has made a point of not only hiring highly talented and dedicated individuals, but those who are passionate about making a positive impact on our work culture and long-term vision. Together, we have created more than just a successful SaaS company, but a family that extends to the fulfillment operations we serve.

Thank you Erhan Musaoglu for taking the time to field our question barrage! Our friends at Logiwa can be found at their website, and if you are debating whether or not you need a tier-2 WMS – or any tier for that matter – please feel free to drop them a line or alternatively we are easily found here.

Written By James Prior

With over two decades in software pre-sales and implementation since 2000, James specialized in working with pre-sales teams and contributed to blog posts. For further information, please email sales@tryonsolutions.com.

More From This Category

WMS Modifications – Weighing Pros and Cons

In the old days we could get under the hood and tweak away until our ride is running exactly how...

Using a WMS to Help Calculate Safety Stock

This past year we've been seeing warehouses carrying more safety stock to help offset...

A Big Question for Multi-Warehouse WMS Implementations

The strategic planning stage is obviously critical for WMS implementations, and one...