TRYON BLOG

A Guided Tour of Supply Chain Execution Systems

Supply Chain Execution (SCE) systems are behind the process workflows of goods going from procurement to delivery in the supply chain. SCE comes after Supply Chain Planning (SCP), and both are under the umbrella of Supply Chain Management (SCM) systems.

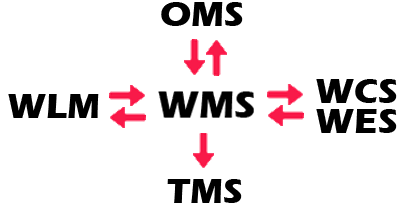

In this article we’ll breakdown the various systems in the Supply Chain Execution space and go through how they all work together. Please note that we understand in the real world there can be a wide variety of other solutions in place (For example Yard Management Systems) as well as other data flows between systems, but for simplicity purposes the interactive diagram above includes strictly the main SCE systems and most common data flows.

Key Systems in Play:

Order Management System – Automates the management of orders along with all the billing-related details throughout their entire lifecycle, from placement to fulfillment. It is arguable as to whether or not an OMS is by definition a supply chain execution system like the other systems we’ll look at, but certainly it is very commonly paired with a WMS in the real world.

Warehouse Management System – In many ways the WMS is the “brain” as it manages and streamlines day-to-day operations in a warehouse or distribution center, and “guides” inventory through receiving, put-away, inventory management, picking, and shipping while optimizing processes and advising on inventory replenishment.

Warehouse Labor Management System – Efficiently applies performance metrics to human labor ensuring that productivity targets are satisfied, and provides warehouse managers with handy dashboards for labor forecasting and planning.

Transportation Management System – Manages, executes, and optimizes the inbound and outbound flow of goods while allowing visibility into all transportation operations (land, sea, and air), including compliance and documentation, with the end goal of ensuring on-time deliveries at maximum value.

Warehouse Execution System / Warehouse Control System – A WES organizes and directs the requisite resources (including people and automation systems) required to move goods through a warehouse. A WCS is doing basically the same thing, but is more limited in scope as it focuses on select pieces of machinery; whereas the WES takes the overall warehouse picture into account.

Let’s look at a basic start-to-finish example:

The customer places an order which is processed in the OMS, and once verified it is then sent to the WMS which checks inventory availability and directs the warehouse operations including picking, packing, and shipping.

The relevant information, most importantly items to be picked and their locations, is then sent from the WMS to the WLM which optimizes labor resources by assigning tasks, scheduling shifts, and monitoring workforce productivity.

Warehouse personnel picks from the rack directly to a WCS controlled conveyor system that goes straight to packing, and the conveyor knows when and where to send the items for each order to be packed as it received this information from the WMS.

Once the order is packed and ready to go out, the WMS hands off the requisite shipping details to the TMS, which handles the transportation and overall outbound logistics aspects, including carrier selection, route streamlining/optimization, and tracking.

Where are SCE systems headed?

In the 1980s there were basic inventory management systems that were focused strictly on inventory tracking, and so the need for more sophisticated systems arose as industries grew, globalization expanded, and supply chains evolved. Simply tracking the widget is nice, but wouldn’t it be even better to tell warehouse personnel where to store it and the best route to take when doing that? The ongoing evolution of supply chain systems remains a pressing reality, particularly in today’s rapidly advancing technological landscape. It’s not just about staying relevant; it’s about ensuring your competitive edge in the face of relentless competition.

True machine learning and AI are on the visible horizon, but four trends we’ve noticed right now with SCE systems include…

…Improved overall ease-of-use and more streamlined interfaces. Warehouses are experiencing unprecedented turnover these days, and new personnel have to be brought up-to-speed on systems faster.

…More out-of-the box automation support and easier interfacing with automation in general. The rise of automation is in line with the rise of automation support in supply chain execution systems. One day there will be a common API toolbox for all of the various warehouse robotics and automation platforms, though it’s doubtful it will be open source because money.

…Configuration rather than costly, time-consuming customization. Tier-2 WMSes are already here, and the handful of tier-1 WMSes out there (Blue Yonder, Manhattan, etc…) are moving this direction. Unless it’s a “must have” modification/customization, it’s just easier to turn a dial or flip a switch versus paying for a specially programmed feature that is likely hard to maintain.

…Continued move to the Cloud. Certainly, if your company uses an OMS, WMS, WLM, and/or TMS you have noticed this shift. The advantages are clear if you trust your SCE system vendor.

What supply chain execution systems does your operation use? Is your team considering one or more of the SCE offerings? Drop us a line, as this is our specialty.

Written By James Prior

With over two decades in software pre-sales and implementation since 2000, James specialized in working with pre-sales teams and contributed to blog posts. For further information, please email sales@tryonsolutions.com.

More From This Category

13 Burning Questions for a Pioneer in Warehouse Modernization

Trevor Blumenau is a professional engineer with a master’s degree in robotics from UC Berkeley and has 25 years of R&D experience in warehouse/manufacturing processes, controls, and innovation. Trevor founded Voodoo Robotics to modernize warehouse operations by...

A Guide to Warehouse Management System Tiers

We’ve defined what a Warehouse Management System is and exhaustively covered supply chain execution acronyms, and so now we must tackle a somewhat nebulous and potentially confusing related subject: Warehouse Management System tier classifications.What is the...

Why Would You Need a Labor Management System?

Delivering a product to the right place at the right time efficiently can take more than just having a Warehouse Management System (WMS) in place. In today’s ultra-competitive environment, which includes an uncertain labor market, your warehouse must fully maximize...