TRYON BLOG

Performance Testing Your Warehouse Management System

We’ve made the case for automated testing in various blog articles with a regression testing focus, but we can’t neglect the importance of performance testing. It’s critical for warehouses to determine for their supply chain systems an answer to the question: At what point do they meltdown? You don’t want to find out the hard way during peak season.

Conducting manual performance testing is possible of course, but bringing in a second shift on the weekend is costly and not very precise. The very nature of determining speed, reliability, scalability, and resource usage is what automated tests are perfectly designed to tackle. The process of finding system benchmarks and breaking points demands the consistency and precision afforded by automated testing.

Let’s level set on some terms underneath the umbrella of Performance Testing:

Volume Testing consists of pumping huge amounts of data through the system quickly, and then analyzing throughput including response times, data loss (if any), and how the database held up.

Load Testing simulates real-world amounts of load to the systems under test.

Stress Testing is focused on determining the upper limit breaking points for system reliability and stability. In this type of testing overall load is increasingly applied to a system with the goal of finding saturation points, locks (often related to users), bottlenecks and ultimately at what point does the system finally crash while the “load dial” is being turned up.

Why try to bust the seams by performance testing?

- Establish performance metrics

- Stress test infrastructure

- Validate an entire system of core WMS business processes working together and related configurations

- Reduce both business risk and labor hours

- Handles purge/reload of golden dataset as well as data positioning

What’s cheaper and more accurate…

This:

Or This:

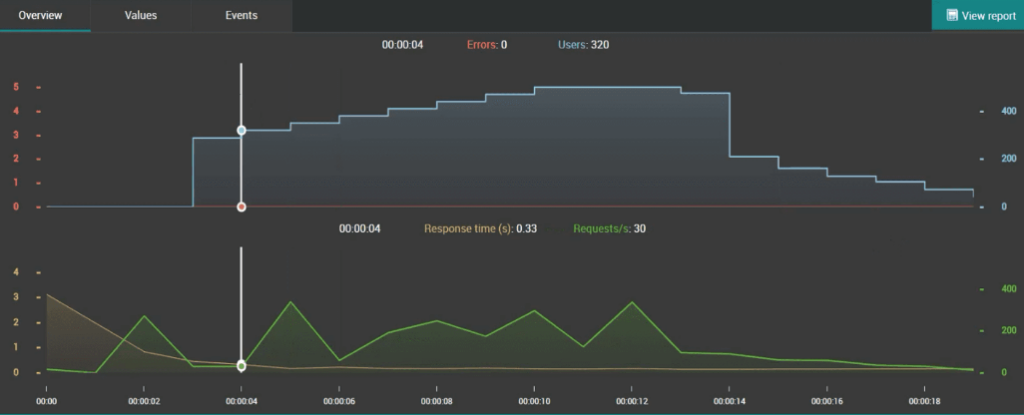

A Tryon customer purchased new servers, and they needed to stress test them to ensure that the upcoming holiday rush wouldn’t result in costly crashes. We created a performance test for them that included emulating 300 mobile devices all executing receiving, putaway, various types of picks, packing, and outbound operations at the same time; mimicking a warehouse in full operation. Server response time and CPU utilization was closely monitored as the dial was turned up (AKA more devices came online). The performance test validated up to 500 WMS users all working in a warehouse at the same time. This handy test can now be run at any time ensure that changes made to the system, whether WMS upgrades, database tweaks, and/or hardware infrastructure, don’t result in pricey outages/downtimes.

We regression test parts of our systems, but why not test the whole system in its entirety. Since we can simply and cheaply press a button to run the test, followed by clearing and restoring the data (“golden dataset” method), and then run it again… Why not regularly performance test your WMS to comprehensively and holistically identify and eliminate issues?

Worried about the impact of seasonal peaks, new product launches, and/or just daily operations? Drop us a line and we’ll help confirm your system and concurrent operations are capable while identifying system weaknesses so you can mitigate risks before production peaks and costly issues arise.

Written By James Prior

With over two decades in software pre-sales and implementation since 2000, James specialized in working with pre-sales teams and contributed to blog posts. For further information, please email sales@tryonsolutions.com.

More From This Category

13 Burning Questions for a Pioneer in Warehouse Modernization

Trevor Blumenau is a professional engineer with a master’s degree in robotics from UC Berkeley and has 25 years of R&D experience in warehouse/manufacturing processes, controls, and innovation. Trevor founded Voodoo Robotics to modernize warehouse operations by...

A Guide to Warehouse Management System Tiers

We’ve defined what a Warehouse Management System is and exhaustively covered supply chain execution acronyms, and so now we must tackle a somewhat nebulous and potentially confusing related subject: Warehouse Management System tier classifications.What is the...

Why Would You Need a Labor Management System?

Delivering a product to the right place at the right time efficiently can take more than just having a Warehouse Management System (WMS) in place. In today’s ultra-competitive environment, which includes an uncertain labor market, your warehouse must fully maximize...

0 Comments